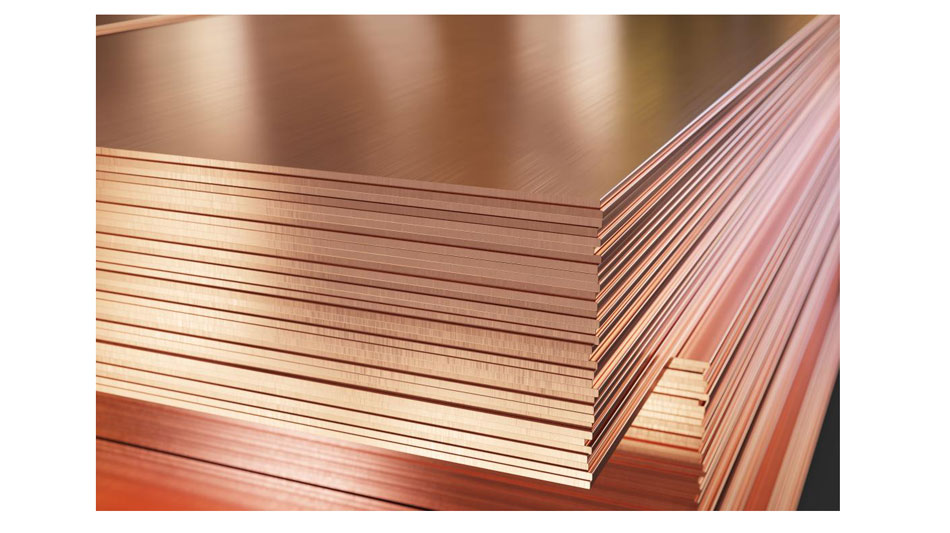

Clàr copaidh tiugh agus duilleag copair leud

1.Wuiredly air a chleachdadh ann an càbaill tricead rèidio, cruth-atharraichean, fealladairean, càbaill leabhidhean hi-fi, conaltradh, luchd-reic tricead, msaa

2.function: Tha e freagarrach airson stuthan sgaoilidh cumhachd a dhèanamh, pàirtean Stiùiridh, stuthan dealain agus stuthan dealanach agus co-phàirtean le crìonadh,

| (mm) Tighead | (mm) Teller acence | (mm) Leud | (mm) Teller acence | (mm) Faid Pannal | (mm) Tòre EneE | ||||||

| 0.1 ~ 0.15 | ± 0.003 | 17 ~ 90 | ± 0.03 | 800 ~ 3200 | ± 1 | ||||||

| 0.16 ~ 0.4 | ± 0.005 | 91 ~ 150 | ± 0.05 | ||||||||

| 0.41 ~ 0.8 | ± 0.015 | 151 ~ 300 | ± 0.1 | ||||||||

| 0.8 ~ 1.5 | ± 0.03 | 301 ~ 1350 | ± 0.2 | ||||||||

| 1.51 ~ 4.0 | ± 0.05 | ||||||||||

| 4.0 ~ 15 | ≤1800 | ||||||||||

| Beachdan: Cuir fios thugainn ro làimh ma tha riatanasan sònraichte ann mu fhulangas thoraidhean. | |||||||||||

| Alloy | Sgeachdadh ceimital & togalaichean corporra | |||||||||||||

| Cu | P | 0 | [g / cm²] SÒNRAICHTE | [% Iacs] Earcessivity dealain | [μx.cm] Cuir an lùib | [Kn / mm²] Modal elasticity | ||||||||

| C11000 | ≥99.90 | ... | ... | 8.94 | ≥98 | 1.75 | 117 | |||||||

| C10200 | ≥99.95 | ≤0.001 | ≤0.001 | 8.94 | ≥100 | 1.724 | 117.2 | |||||||

| Alloy | Temper | RM / (N / MM²) Neart teasile | A₁1.g /% Eondongtion | Cruas | |||||||||||

| GB | JIS | Astm | Gb | JIS | Astm | GB | JIS | Astm | GB | JIS | Astm | Gb (hv) | JIS (HV) | Astm (HR) | |

| T2 | C1100 | C11000 |

| 0 | 061 | ≥195 | ≥195 | ≤235 | ≥30 | ≥30 | ≤70 | .. | .. | ||

| Y4 | 1 / 4h | H01 | 215-275 | 215-285 | 235-290 | ≥25 | ≥20 | 60-90 | 55-100 | ||||||

| Y2 | 1 / 2h | H02 | 245-345 | 235-315 | 255-315 | ≥8 | ≥10 | 80-110 | 75-120 | ||||||

| Y | H | .. | 295-380 | ≥275 | .. | ≥3 | 90-120 | ≥80 | |||||||

| T | .. | ≥350 | .. | .. | ≥11010 | ||||||||||

| TU1 | .. | .. |

| .. | .. | ≥195 | .. | .. | ≥30 | .. | .. | ≤70 | .. | .. | |

| Y4 | 215-275 | ≥25 | 60-90 | ||||||||||||

| Y2 | 245-345 | ≥8 | 80-110 | ||||||||||||

| Y | 295-380 | ≥3 | 90-120 | ||||||||||||

| T | ≥350 | ≥11010 | |||||||||||||

| TU2 | .. | .. |

| .. | .. | ≥195 | .. | .. | 多 30 | .. | .. | ≤70 | .. | .. | |

| Y4 | 215-275 | ≥25 | 60-90 | ||||||||||||

| Y2 | 245-345 | ≥8 | 80-110 | ||||||||||||

| Y | 295-380 | ≥3 | 90-120 | ||||||||||||

| T | ≥350 | ≥11010 | |||||||||||||

| TU3 | C1020 | C10200 |

| 0 | H00 | ≥195 | ≥195 | 200-275 | ≥30 | ≥20 | .. | ≤70 | .. | .. | |

| Y4 | 1 / 4h | H01 | 215-275 | 215-285 | 235-295 | ≥25 | ≥15 | 60-90 | 55-100 | ||||||

| 1 / 2h | H02 | 245-345 | 235-315 | 255-315 | ≥8 | ≥10 | 80-110 | 75-120 | ||||||

| H | H03 | ≥275 | 285-345 | 一 | ≥80 | ||||||||||

| Y | H04 | 295-380 | 295-360 | ≥3 | 90-120 | ||||||||||

| H06 | 325-385 | ||||||||||||||

| H08 | ≥350 | 345-400 | .. | ≥11010 | ||||||||||

| H10 | ≥360 | ||||||||||||||

| Beachdan: Cuir fios thugainn ro làimh ma tha riatanasan sònraichte ann air feartan thoraidhean. | |||||||||||||||

Sgrìobh do theachdaireachd an seo agus cuir thugainn e